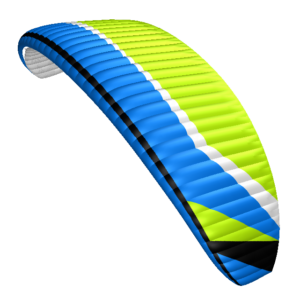

Nemo XX

Nemo XX

Nemo XX is recommended as your first purchase after initial training, the more so if your school used it. There is still a lot of its capabilities you will be able to discover, while staying satisfied with its safety, performance and versatility in various forms of recreative flying.

Design and purpose

It will forgive you a lot of your mistakes and make you ready for further stages. It will let you spend many hours of stress-free winching, thermalling, cross-country and PPG flying. And it will be reasonably priced at that.

Nemo XX is a certified fun paraglider of EN A class, with modern design, good performance and great safety. It is distinguished from earlier Nemo by better glide ratio, agility and even easier launch. It is dedicated for the beginners and recently trained pilots – it can be used for training, winching and paramotoring.

The three-row canopy with rigid rods (Dudek FlexiEdge technology) incorporates current experience won while designing and testing three- and two-row prototypes of high performance paragliders.

Inner reinforcements, structural rods and mini-ribs make sure that the aerofoil is precisely reproduced and stabilized in flight. Three-row rigging of reduced drag increases performance. Mini-ribs on the trailing edge make for slim canopy with minimal ballooning and improved airstream. All those solutions result in exceptional performance in its class, still fullfilling the harsh requirements of EN-A class safety (as so-called “upper A”).

When designing Nemo XX we put a lot of work into flight safety, effective steering, easy operation and attractive look of the paraglider. In a number of prototypes leading to final Nemo XX version we’ve tested several airfoils, shapes and curvatures of the canopy for their stability and resistance to turbulences in various flight configurations. Additionally, selected airfoil was examined and optimised with dedicated CFD (Computational Fluid Dynamics) software.

Advanced engineering merged with Piotr Dudek years of designer experience resulted in a paraglider of perfectly stabilized canopy, ideally suited to pilot’s expectations of this class.

CERTIFICATION

All sizes have passed the certification procedures, receiving EN/LTF A category.

LAUNCH

The launch is pretty easy, with some practice it is not necessary to keep the risers up, as the canopy comes up on its own and waits for you in the nadir.

STEERING

Nemo XX is a responsive and agile wing, smoothly reacting to all pilot’s actions. Steering is light and pleasant, with steering forces growing proportionally to brake input. Adding some weightshifting makes the turns faster and tighter.

DESIGN

A set of design tools called Canopy Shape Guard effectively stabilizes the wing along its entire span, practically eliminating any lateral canopy movement. Below you will find short descritpion of its components.

Nemo XX has an elliptic-shaped wing with slightly swept tips. The cells are divided in two, with ribs additionally supported with the VSS system (V-Shaped Supports). Such design ensures the upper surface smoothness, precise airfoil reproduction along the entire wingspan, better load distribution and what’s important, as few line attachment points as possible.

On the lower surface, in the wing’s interior there is a RSS (Reinforcing Strap System) – an independent reinforcement net strengthening and stiffening the whole canopy. These reinforcements are made of straps of cloth.

The airfoil of th canopy is based on the DOA (Dudek Optimized Airfoil) technology. It was designed basingn on our expeirence with both previous and current models, then opimised with dedicated CFD software.

The suspension points are reinforced with laminated cloth, and the loads are spread equally in three planes: vertically through the ribs, diagonally through the VSS system and horizontally, through the RSS system.

The the intercellar openings are made under OCD system (Optimised Crossports Design), caring for carefully designed shapes and optimal placement between stress lines in the ribs. Such openings guarantee efficient distribution of pressure within the canopy and its quick filling. The crossports are scales together with the ribs, so their shape and regularity are flawless and do not disturb the airfoil.

Nemo XX is made with Flexi-Egde technology. The leading edge is closed to the airflow, and its precise shape is kept with laminated cloth reinforcements, incorporating synthetic rods. The rods make the leading edge stiffer and smoother, improving the launch protecting the canopy against deformations at high speeds.

The air intakes are placed on the lower surface close to the leading edge, placed so that max pressure point remains in the area at possibly many states of flight. They are designed and executed in Shark-nose technology meaning specific, concave shape of the reinforced profile area at its leading edge (the name comes form the very shape, reminding shark’s nose). Due to such shape the intakes can be smaller and moved a bit back, so that leading edge remains undisturbed and offers smooth airflow. The internal pressure of the canopy stays stable within wide speed range. In everyday flying this results in greater resistance to stalls (e.g. when thermalling) and front collapses at high speeds.

At the wingtips there are additional ACS openings (Auto Cleaning Slots), automatically removing dirt from the inside of the canopy.

Careful selection of the modern cloth and design ideas made sure the Nemo XX will have great durability. All materials used come from numbered batches, and each production stage can be verified down to identification of individual worker and supervisor.

Nemo XX is manufactured in new technology, using precise laser plotter. The whole production process takes place in Poland under watchful eye of the designer himself, ensuring highest European quality.

The paraglider is made of Dominicotex and Porcher companies cloth, with great operational parameters.

Parameters

TECHNICAL DATA

| Nemo XX – size | 20 | 23 | 25 | 28 | 31 |

| Certificate EN/LTF | A | A | A |

A |

A |

| DGAC approval | yes | yes | yes | yes | yes |

| Number of cells | 42 | 42 | 42 | 42 | 42 |

| Surface flat [m2] | 20.60 | 23.00 | 25.30 | 28.00 | 31.00 |

| Surface projected [m2] | 17.52 | 19.56 | 21.52 | 23.82 | 26.37 |

| Wingspan flat [m] | 10.20 | 10.78 | 11.30 | 11.89 | 12.51 |

| Wingspan projected [m] | 8.00 | 8.46 | 8.87 | 9.33 | 9.82 |

| Aspect ratio flat/projected | 5.05 / 3.65 | ||||

| Sink [m/s] | min = 1.1 +/- 0.1 | ||||

| Speed [km/h] | trym = 37 +/- 2 ; max = 47 +/- 2 | ||||

| Longest chord [cm] | 249.80 | 264.00 | 276.90 | 291.30 | 306.50 |

| Shortest chord [cm] | 58.70 | 62.00 | 65.10 | 68.40 | 72.00 |

| Lines length (incl. risers) [m] | 6.17 | 6.52 | 6.84 | 7.19 | 7.57 |

| Total lines length [m] | 221.52 | 233.43 | 245.06 | 258.66 | 272.48 |

| Canopy weight [kg] | 4.4 | 4.8 | 5.2 | 5.6 | 6.0 |

| Take-off weight EN/LTF [kg] | 48-72 | 55-75 | 70-90 | 85-110 | 100-135 |

| Take-off weight DGAC* [kg] | 45-85 | 55-95 | 70-110 | 85-130 | 100-155 |

| Lines | Technora: 1,2 & 1,3 & 1,5 & 1,8 & 2,3 | ||||

| Cloth | Porcher 38, Dominicotex 34 | ||||

* DGAC – French Civial Aviation Directorate responsible for air traffic safety and management. Since 2011 charged with certifying microlights.