When repair or inspection is necessary, please contact your Dealer. He will assess the situation and advise on further actions (consulting us when necessary).

Most often, an inspection or minor repair will be available not far from your location. Also you can contact us at service@dudek.eu

NOTE – do not send anything to us before an agreement is reached on optimal procedure.

When sending the canopy to the dealer or company service center please fill our the form linked below. It will be very helpful in assembling all details concerning proposed repair or inspection.

Download the repair order formInspections and Repairs

The inspections and guarantee repairs are conducted in our plant at Kowalewo, or by:

- RIP’AIR company, ZA de Perroix, 74290 TALLOIRES, France, tel. +33 (0) 450 64 41 02, fax +33 (0) 450 64 41 17, e-mail: info@ripair.com, www.ripair.com

- THE LOFT, Mike Milwood, Church Hill, Newhaven, East Sussex, BN9 9LN, United Kingdom, Tel. 01273 858620, e-mail: mailto:info@theloftworkshop.co.uk, http://theloftworkshop.co.uk/

Note! If paraglider have to be delivered to our production plant, please send it to this address:

POWAIR Sp. z o.o.

ul. Leśna 5, 89-200 Kowalewo k/Szubina

POLAND

We consult the wing owner by telephone or mail before starting any major repair.

Each paraglider sent to us should be accompanied by:

- the form mentioned above

- the last inspection report

- the airworthiness statement (Oznaczenie zdatności) card.

- NOTE: free-of-charge procedures covered by Aero Casco or Warranty need some other documents too, mentioned in the sections concerning these features and in manual.

Parcels sent to our factory can be dispatched via any courier service. After the inspection, the wing or reserve parachute is sent back to its owner.

Since we do not have authorisation from any other paragliding company, all inspections and repairs are limited to our own products. The exception is the porosity test, carried out for all makes.

Inspections are performed immediately on receiving the gear. We know how precious for any pilot is every day of flying weather, so all inspections are given highest priority.

copy link

Sorts of Inspections

Full Inspection – thorough technical check

The Full Inspection is recommended every 24 months or 150 hours airtime (whatever comes first), given that no other schedule was specified for the paraglider and the inspecting person has not advised otherwise due to paraglider’s condition.

In case of paragliders used commercially (e.g. in schools or tandem flying), a Full Inspection is recommended each year after first 24 months since purchase date or every 100 hours airtime (whatever comes first).

All inspections must be done by the manufacturer or an authorised dealer (qualified to carry out an inspection).

Full Inspection range:

A. visual canopy check, lines symmetry check

B. cloth porosity test

C. lines length measurement

D. cloth strength test

E. suspension lines strength test

F. symmetry test

Inspection range can be extended at any moment if doubts arise concerning the wear of the wing.

Extra Inspection

This examination is carried out on demand (for example before buying or selling the wing). Standard are A, B and C procedures. For a special request from user range can be extended.

Extra inspection can be advised by inspecting person if doubts arise concerning the wear of the wing.

After Repair Inspection

This is an obligatory element of repair service. Inspection range is determined by the repair procedures.

Results of the inspection will be stated in written protocol.

Zero Inspection (post-production check out)

To be precise – there is one more type of inspection: first, post-production check out, named Zero Inspection. It is usually valid for 24 months from the date of manufacture of the wing. For some wings, the period of validity of this inspection is shorter – it is specified in the data sticker sewn into the wing.

Zero Inspection consists of:

1. Wing edges symmetry and length check

2. Left and right side lines symmetry check

3. Suspension lines length check

4. Wing surface quality check

5. Suspension lines condition check

6. Risers and speed-system visual check

Paraglider Identification

The paraglider model and serial number are to be found on wing sticker, placed inside the wing chamber around the center. The sticker must be filled out completely and clearly. In case of legibility problems, the numbers can be confirmed in our database.

You can find out more about the wing by entering its number in our search engine.

Suspeniosn Lines Breaking Strength (Destruction Test)

Each AP1, AD1, AT1 and BP1, BD1, BT1 line is dismantled and examined. If any of these lines has been replaced earlier, or shows any damage, the next line of the same row and layer is taken.

Breaking strength is measured with a specialized device. If any of the lines do not comply (will break at less than 30 daN) we have also to check the other lines of the same row and layer. In case of doubts all lines of given group are replaced.

Of course, the lines broken on test are replaced too. Only the original lines used by Dudek Paragliding can be applied and proper stitching must be observed.

copy link

Porosity Test

Wing porosity is understood as air permeability of the cloth, measured in l/m2/min (litre per square metre per minute) under standard pressure of 200 mm water column, that is 20 mb.

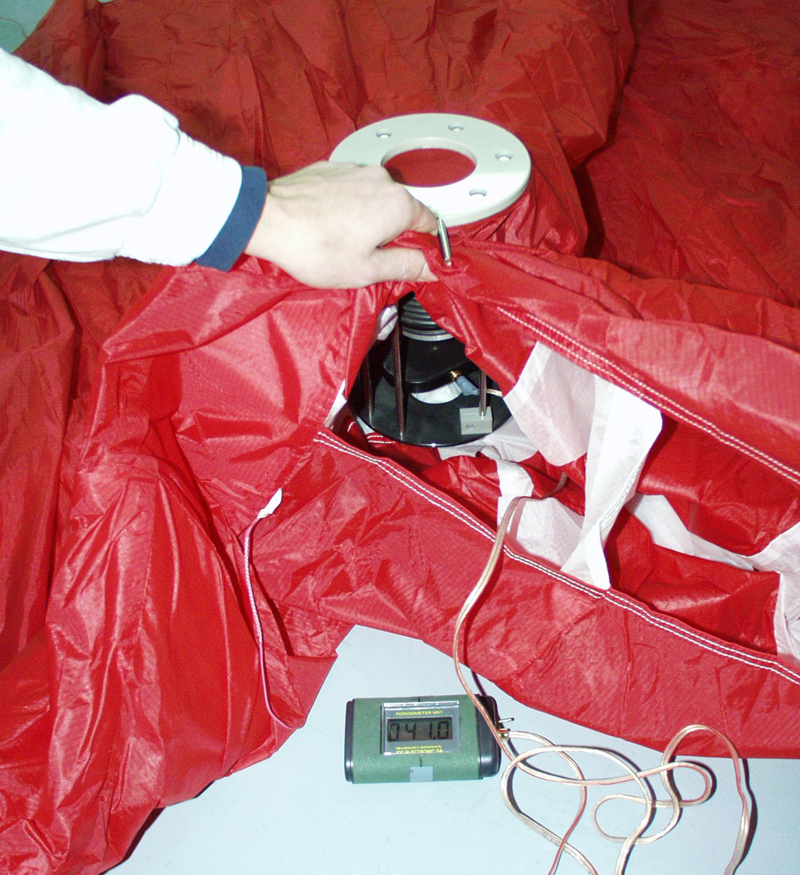

The measurement is taken with a POROSIMETER JDC MK-1 (rev.A), produced by Swiss JDC Electronic S.A. company (www.jdc.ch). It works with a 100 mm water column pressure (10 mb) and is an improved version of this device, characterised by a stronger magnet and better fitting, eliminating undesired air flow between cloth and device corpus.

The result is given in seconds needed for 0.25 litre of air to permeate through cloth of 38.5 cm2 area under 10 mb pressure. It is then recalculated into standard units and 20 mb pressure with the formula: permeability [l/m2/min] = 5400 / time of measurement [s]

The measurement is taken on the upper surface of the wing in three cells: centre (half of wing span), 1/4 wing span and the last open cell (closest to the stabiliser).

The device is mounted at midpoint on the wing chord. Before commencing measurement this place must be checked, as even the smallest tears can drastically alter the results. It is advised to look at the cloth against the light.The results are then recalculated to obtain an arithmetical average, that will describe the wing porosity. If any of the results radically differ from the average, the site of measurement on the wing surface must be carefully checked again and possibly changed.

Following table is used in interpreting the results:

0 – 20 (0 – 39)*- “as new” cloth condition

20 – 50 (40 – 89)*- excellent cloth condition

50 – 100 (90 – 179)*- good cloth condition

100 – 150 (180 – 269)*- satisfactory cloth condition

150 – 300 (270 – 539)*- well-used cloth, paraglider airworthy

300 and above (540 and above)*- worn-out cloth, safety cannot be guaranteed

(…)* – ranges for single skin paragliders (monoskins).

Dudek Paragliding considers airworthy only paragliders with porosity of less than 300 (or 540 for monoskins) [l/m2/min].

All the information is included in a porosity report.

copy link

Bettsometer Control

The measurement is taken on the upper surface of the wing in three cells: centre (half of wing span), 1/4 wing span and the last open cell (closest to the stabiliser).

The device is mounted at midpoint on the wing chord. Before commencing measurement this place must be checked, as even the smallest tears can drastically alter the results. It is advised to look at the cloth against the light.

One needle with a sharp tip is straight and mounted in the head of the device. With this needle the cloth resistance is tested.

The other needle has a blunt tip and is hooked. With this one the stitching strength is tested.

What we measure with this device is the force needed to break the cloth fibres, and practically its tear resistance under a minimal, predetermined force.

In order to take the measurement, the straight needle is driven into a stretched piece of cloth, and then the balance is loaded up to 600 g. If the cloth will not tear, the test is considered positive (passed). It is to be made in three places on the top surface above the air intakes, and in three places on the lower surface near the suspension points of the A row.

If the cloth breaks in any of tested places, the paraglider is no longer considered airworthy.

The stitching is examined with hooked needle. The hook is driven between the folds, and balance is loaded up to 1000 g. If the stitching holds, the test is successful. It is to be made in three places on the top surface in the vicinity of leading edge.

Visual Control

The paraglider is hung up and filled with air. We also use additional lighting behind the wing, which is substantial to find all tears and holes.

Both top and under-surface are carefully checked in respect of damage, including:

- scars, tears, holes and any other damage,

- suspension points condition,

- random stitching check on top and under surface,

- condition of the ribs,

- seams on all air-intake reinforcements (Mylar); in case of any doubts they must be replaced.

Tears on both surfaces can be repaired with self-adhesive tape by the user, provided that they are max. 5 cm long and no closer to the ribs than 5 cm. To fix it you have to choose a shape that will cover the damage with 5 cm to spare and place the tape firmly on both sides of the cloth.

Major damage has to be repaired by the manufacturer, as it often requires replacement of whole panels. Similar action must be taken when the ribs are damaged.

copy link

Wing Edge Symmerty and Length Check

The wing edges are measured to confirm that the paraglider conforms to the plan and thus fulfills certification requirements.

Left and right side lines symmetry check

Both risers are hooked together so that they remain in equal position and distance from the measuring person. Then the lines of right and left side are

slightly stretched, to check that their length remains the same.

After that we free the risers and hook the brakes together, to be checked in the same way.

copy link

Suspension Lines Condition Check

The paraglider is hung up and the lines are sorted out. Then each line is examined as follows:

- visual check (sheath, stitching, tears)

- manual check (any changes in the core)

- positioning of the brake handles (should be fastened at the original marks, this length is controlled).

In case of any doubts the lines are replaced.

Measuring of suspension lines length (with electronic device)

Both risers are hooked together so that they remain in equal position and distance from the measuring person. Then the lines of right and left side are slightly stretched, to check that their length remains the same.

After that we free the risers and hook the brakes together, to be checked in the same way. Differences greater than 10 mm are automatically pointed out with change of background colour. All results are then saved in proper files.

This examination is considered positive when max. variation from expected value does not exceed 30 mm, and the difference between maximum variations is no greater than 15 mm.

At Dudek Paragliding we measure lengths with Eng. Peter Worner’s electronic device. The measurement is taken when the lines are being strained with 5 daN force for 0.5 seconds. The measurement can be taken manually, provided that it is carried out under a 5 daN strain.

If the less-loaded suspension lines (most often of C and D rows) are shown to be considerably shortened, they can be stretched back to their original length with a 20 daN force. The stretching must be done symmetrically, and afterwards the lines must be measured again. Nevertheless, we urge the pilot to avoid factors that cause shrinking of the line sheath (especially excessive humidity).

Noticed irregularities in the lines are examined manually and the lines are replaced when necessary.

Canopy finish quality control

Stitching together a great number of wing parts is a difficult process, requiring great precision. In every such activity there is a chance of making mistakes, which have to be found on Zero Inspection.

copy link

Risers and Speed-System Check

We do examine the following elements:

- wear damage to risers as a whole,

- places of contact with steering lines (if some fibres are melted or hardened, this is a sign of high temperature and friction, so the entire riser is to be replaced),

- end loop of the risers (whether they are damaged by carabiners),

- smooth operation of steering lines and speed-system pulleys,

- speed-system cord length (cannot be strained when the riser is loaded) and overall quality (as any damage to the line sheath, e.g. caused by Velcro zips, can shorten the cord),

- all seams of the risers (if in doubt, the entire riser must be replaced),

- closure of the quick links (should not be opened by bare hands),

- o-rings holding the lines on the quick-links together (they stiffen in time).