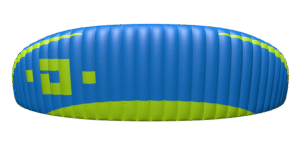

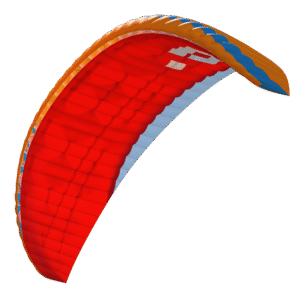

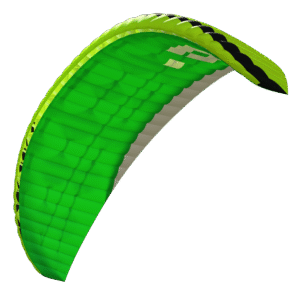

Halo

Halo

Halo was created with paragliding schools in mind, looking for the most user-friendly training wing possible.

Design and purpose

For the Halo, the keyword that guided us during the development phase was “ease of use”. The design goal was to facilitate the work of the instructors by facilitating the apprenticeship of the students. This requested extensive design work involving many numerical simulations. It was followed by numerous hours of trimming on the ground and in the air in a wide variety of conditions and flying spots, notably in the French Alps and in Poland.

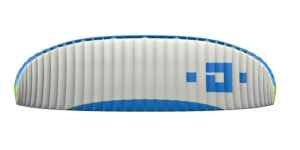

Certification

All sizes have passed the certification procedures, receiving EN/LTF A category.

Design solutions

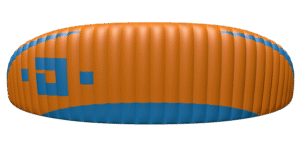

We paid special attention to details that, in our opinion, are of great importance.

Among other things, the separate risers for the “big ears” are intentionally longer than the others, which makes them easier to identify and use, especially for beginner pilots. The handles have been equipped with a double strap attachment system: Easy Keeper magnets and snaps, ensuring safety and comfort.

The Dudek Paragliders team strongly recommends regular ground training – regardless of the pilot’s level of advancement. They improve technique, increase the pleasure of flying, and provide a lot of satisfaction.

Careful selection of the modern cloth and design ideas made sure the Nemo 4 will have great durability. All materials used come from numbered batches, and each production stage can be verified down to identification of individual worker and supervisor.

Main lines are coded with colours according to recent PMA recommendations. More about this initiative on the Association website.

Design solutions, technologies and other functionalities are listed below in the Technologies section.

Construction solutions

Technologies, concepts

Risers functionality

USED SOLUTIONS

Parameters

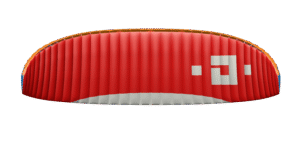

Technical data

| Halo – size | 20 | 23 | 25 | 28 |

| Certificate EN/LTF | A | A | A | A |

| Number of cells | 36 | |||

| Surface flat [m2] | 20.50 | 22.80 | 25.00 | 28.00 |

| Surface projected [m2] | 17.54 | 19.51 | 21.39 | 23.96 |

| Wingspan flat [m] | 9.86 | 10.40 | 10.89 | 11.52 |

| Wingspan projected [m] | 7.89 | 8.32 | 8.72 | 9.22 |

| Aspect ratio flat/projected | 4.80 / 3.55 | |||

| Longest chord [mm] | 2561 | 2700 | 2828 | 2993 |

| Shortest chord [mm] | 441 | 465 | 487 | 515 |

| Lines length (incl. risers) [m] | 5.95 | 6.28 | 6.57 | 6.96 |

| Total lines length [m] | 195.82 | 206.98 | 217.13 | 230.28 |

| Canopy weight [kg] | 4.51 | 4.82 | 5.35 | |

| Take-off weight PG* [kg] | 45-70* | 55-80* | 70-95* | 80-110* |

| Take-off weight PPG*[kg] | 45-90* | 55-100* | 70-115* | 85-130* |

| Maximum symmetric control travel at maximum weight in flight [cm] |

55 | 55 | 60 | 60 |

| Distance between risers [cm] | 40 | 42 | 44 | 46 |

| Lines | Technora: 090/140/190/280 ; Dyneema: 125/180/200 | |||

| Cloth | Dominico tex 30DMF, 30DFM, 3036FM SR Scrim, SR Laminate 180 g/m2 |

|||

* The basic rule is to choose the size of the wing so that the take-off weight is in the middle of the weight range. Less weight on the wing (lower range take-off weight) can be considered for foot take-off, when flying in calmer conditions, or when we want to improve economy. More experienced pilots who want to fly dynamically, have higher speed and fly in more demanding wind conditions can consider greater wing loading (take-off weight in the upper range). This is a common option among trike users.

** Note – the canopy significantly changes its behavior with increasing wing loading. The greater the loads, the greater skill and concentration of the pilot are required.